Cnc Drill Line 9r

Voortman is the only manufacturer of the CNC Drill Line for GSS Machinery. Voortman takes care of all aspects of the CNC Drill Line's installation, warranty, maintenance and repair. Voortman provides the service, but GSS Machinery can always be reached if required.

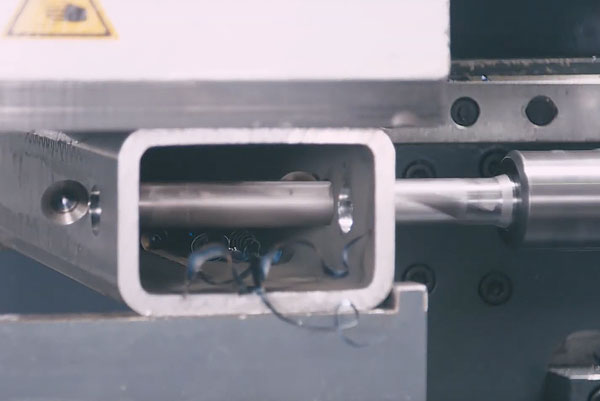

This ability to mill efficiently speeds up project completion. The Advantage-2 user-friendly Raptor 3DCAD/CAM software allows the operator to quickly program parts. The 3D platform allows you to inspect, modify, and export your part information. Advantage-2 drill's greatest advantages are the ability to scribe and mill slots as well as large lifting holes. This machine is truly unique. The scribing allows us to place piece marks, layout lines, and center points. It's been great to have the flexibility to use it whenever we want and to make those decisions.